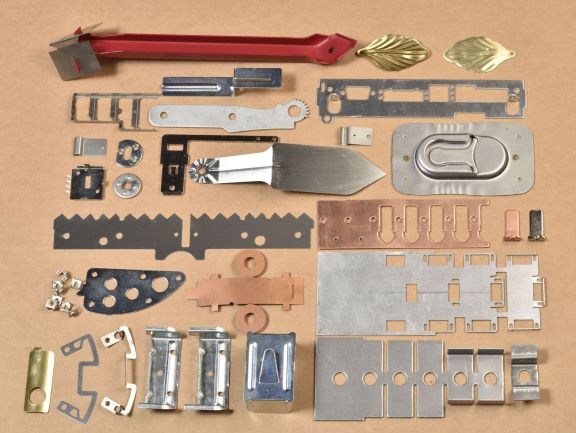

Why metal stamping is a cost-effective method for sheet metal projects

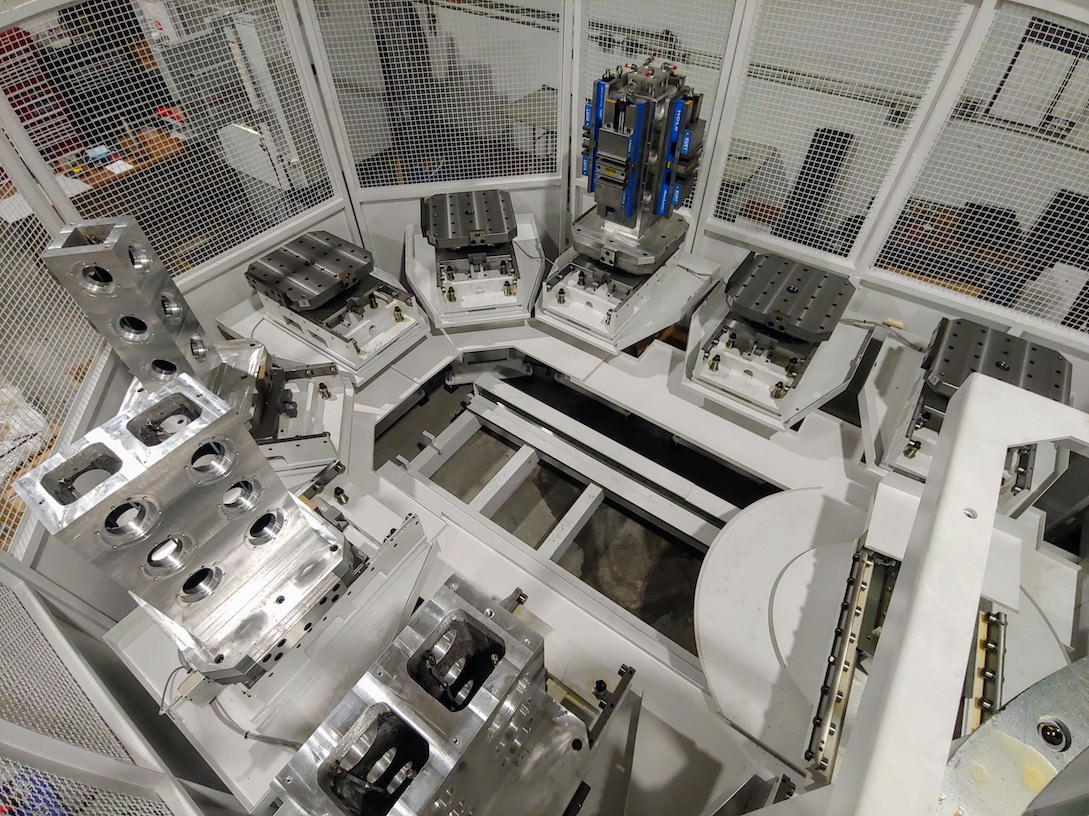

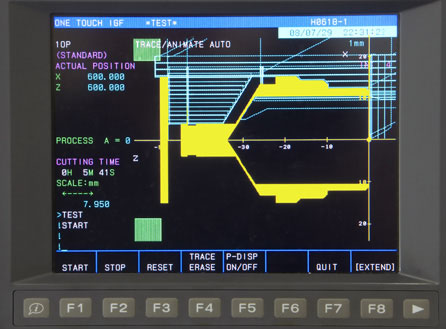

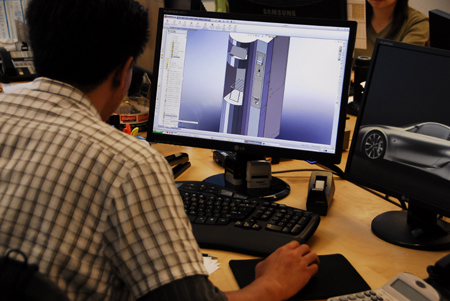

Metal stamping turns flat sheet metal into simple or complex shapes and designs. It can be a cost-effective method of forming sheet metal for your next project because stamped parts typically have higher repeatable accuracy and lower part cost. How metal is stamped We will import your CAD drawings into our metal stamping machines. Accuracy …

Continue reading “Why metal stamping is a cost-effective method for sheet metal projects”