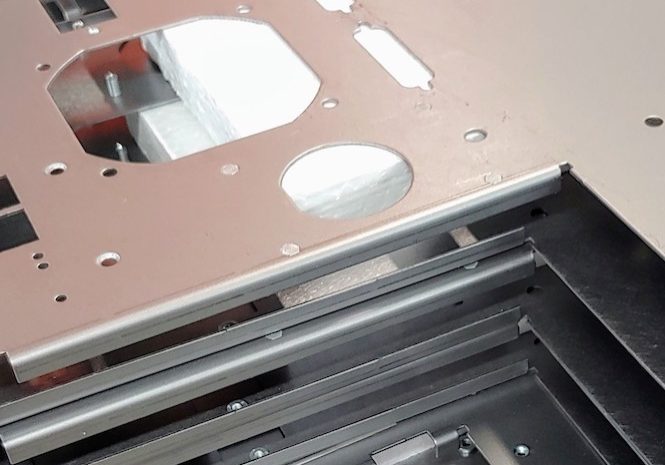

Sheet Metal Fabrication

Although we are a very versatile sheet metal fabricating and stamping shop, we do specialize in electronic enclosures with an average run size of fifty. We prefer dealing with maximum .125" in steel and aluminum. For working with stainless steel, .074" maximum is preferred. The maximum preferred cabinet size based on all manufacturing limitations for production quantities is 72" x 36" x 18".

The Sheet Metal Shop uses Mitsubishi and Trumpf lasers, Trumpf Punch Presses, a SteelMaster In-Line Finisher, Trumpf and Amada Brake Presses, and Pemserter fastener inserters as its’ core equipment.

| CNC Punching (Manual and CNC) | Maximum sheet size | 48" x 120" (1.22m x 3.05m) |

| Maximum thickness | .125" (3.175mm) | |

| Bending (Manual and CNC) | Maximum length | 120" (3.05m) |

| Maximum thickness | .125" (3.175mm) | |

| Welding (Manual and robotic) | Steel, Aluminum, Stainless Steel |

We have three Trumpf CNC punch presses which are programmed using Solid Works 3D modeling, Trumpf's Boost tool-path software and Metamation's MetaCam software. All machines are fully hydraulic and carry the pre-set tools on a linear magazine. As a result of the linear magazine tooling rail, tool setup time is reduced dramatically because tool alignment is done off-line while the machine is running. All tools can be rotated throughout 360 degrees and the machine has the multi-tool option.

The Buetfering Steelmaster In-Line Finisher uses an abrasive belt and rotating and oscillating stainless steel top brushes to grain and debur sheet metal parts. The In-Line Finisher is fully programmable and the parameter tables can be saved.

The Trumpf and Amada brakes have full CNC controls with multi-axis back gauges for quick set-up and repeatable precision. All brake tooling is precision ground and hardened for long life. This tooling combined with the crowning compensation built into the Brake beds allow for repeatable, accurate bending over the full bed length (up to 10 feet).

The Trumpf TruBend 5130 is a ten foot CNC brake press with a six axis back guage. Trumpf TruBend 7036 's are extremely fast electric brakes. The machine has hydraulic clamping of tools, high frame height, off line programming, automatic crowning, laser protection, LED guidance and precision hardened and ground tooling.

We have 3 Pemserter Series 2000 fastener insertion machines with bowl feeders, laser guiding and PLC controls that use hydraulic pressure to insert studs, nuts and stand-offs.

We do Mig, Tig and Spot welding.

We are happy to offer a comprehensive overview of our Sheet Metal Guidelines by request; please email us your request here and we will send you a PDF document.