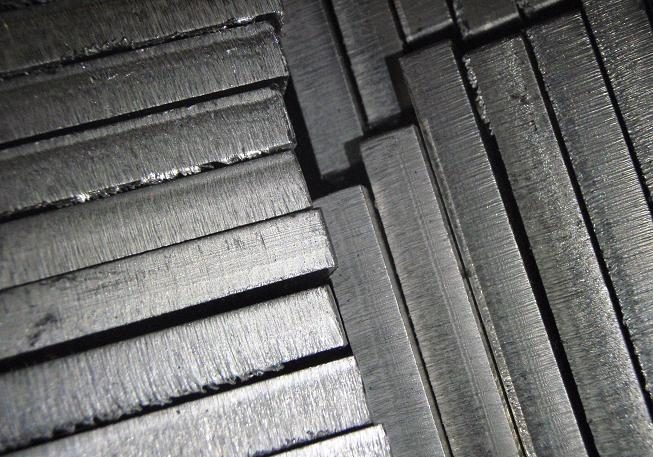

Edge Quality and Burr

These parts are cut on 10 different lasers from 5 manufacturers using 4000 watt and 5000 watts resonators. In laser cutting there is a trade-off between edge quality and burr (dross). Power, dwell time, cutting speed, lens focal length, nozzle size, assist gas, material and material thickness all contribute to the cut quality. You can see some parts here have poor edge quality and a large burr, while others have superior edge quality and no burr. All of these samples are done on 3/8" aluminium.

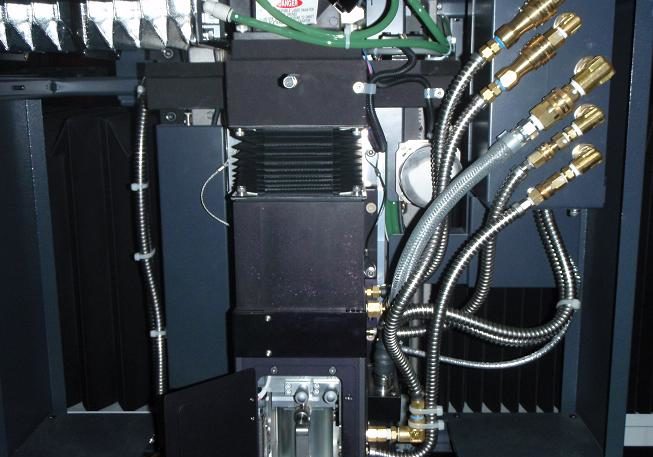

Cutting Area

This is cutting area of the laser which is at the end of the beam path. There are 10 external mirrors once the beam leaves the resonator, each water cooled by the green hoses that you see in the picture. The metal covered hoses are for the different assist/shield gases that are under software control. Typically we use oxygen for steel assisting the cut and blowing the dross out of the burn area. When cutting aluminium and stainless you want to prevent oxidation so nitrogen gas is used which actually cools the cut and shields the cut from oxide formation. We use different focal length lenses and and nozzles depending on the material, thickness, and quality of cut the customer is willing to accept.

Backside of Resonator

The picture above is the back side of the resonator. There is a sensor that monitors the laser power and shuts down the power if there is a back reflection from the liquid material as can easily happen when cutting aluminium.

Side of Resonator

This is the side of the resonator where the beam exits. There are water cooled mirrors and a mechanical shutter to guide the beam into the machine bellows and to protect the resonator.

Sample Components

These are samples of laser cut parts, showing various thicknesses.

Shelf Tower

Our machine has a 16 shelf tower, a load/unload subsystem, and two automated unload tables. Each shelf holds 6,000 lbs of material for a total tower capacity of 96,000 lbs. The over/under unload tables can each hold 11,000 lbs so we can cut 22,000 lbs of material before having to unload.