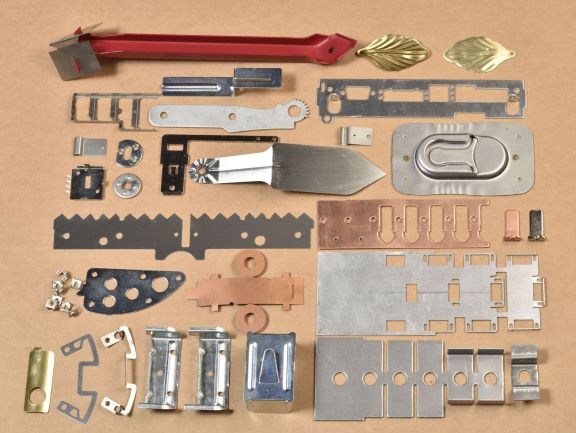

Metal stamping turns flat sheet metal into simple or complex shapes and designs. It can be a cost-effective method of forming sheet metal for your next project because stamped parts typically have higher repeatable accuracy and lower part cost.

How metal is stamped

We will import your CAD drawings into our metal stamping machines. Accuracy is very important, as is using the correct tolerances. Our design team can help ensure your drawings are as precise as possible.

Sheet metal is fed into our metal stamping machines, then it is pressed into the stamping press to form the shapes required. Metal stamping can also include punching, bending, and embossing of the metal.

To get the best value from your parts, we will also work with you to choose the right sheet metal raw material. The sheet metal stamping process is already quite cost-effective because sheet metal costs less than other ways of metal forming, but you could see additional cost savings based on your choice of metal. Common sheet metals include steel, aluminum, zinc, or nickel.

At Hansen Industries Ltd., we have manufactured components for a variety of industries, including electrical, electronics, construction, windows, doors, fishing, marine, medical, dental, and architectural markets. We’d love the opportunity to quote on your metal stamping project.