When metal is cut or stamped, it creates sharp edges called burrs. Even though they are small, burrs can cause assembly problems, interfere with fluid flow, cause worker injury, and can also cause increased stresses and subsequent fatigue failure of the part.

The techs at Hansen Industries will choose the best deburring method to produce the smoothest result of your finished metal. If you have any questions about our deburring methods or about your upcoming metal project, please contact us and we’ll be glad to help.

Here are the different ways Hansen can deburr metal parts:

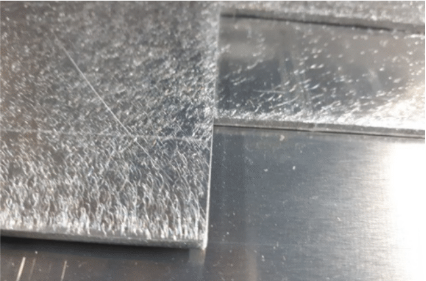

In-line finishing: This process removes spurs on one side of the metal in a single pass. Our machine removes the burrs and cleans the edges of the part. This is done in an automatic, unsupervised cycle.

Vibrating deburring: Like its name indicates, this pneumatic linear vibrating machine is controlled by compressed air and can edge rounding, de-slack, and remove oxide from the part.

Stroke sanding: Our large production sander uses a hand-operated platten on a standard sanding belt to apply pressure to the metal part. It’s an ideal method for large surfaces like tabletops, doors, and cabinets. This method allows us to make deeper depth grinding.

Break Sharp Edges: Some sharp burrs can be removed by moving the belt file down in the part in one motion for flat edges, or several times at different angles for rounded edges.